As with everything else, there is a set of complementary processes that follow each other in packaging. Every step is important from the beginning of packaging design to the moment it is opened by the consumer.

There are five distinct stages that packaging goes through, and each of them has its challenges.

Production

Completion

Transportation

Shelf life

User Experience

What is the significance of each of these steps, and what should a brand consider in each of these steps? Let's examine it one by one.

1. PRODUCTION PROCESS

The first step in the packaging process is the production of the packaging. The manufacturing process must be considered when thinking about the design of the packaging. Some of the factors that will affect the production process are:

- Packaging material or substrate

- The cost of these materials

- Where the packaging will be produced

- The time required to produce the packaging

- Whether to use automation or manual labor

All these factors need to be taken into account when thinking about the design of the packaging. Because this process affects not only the production process but also the overall cost and timeline of the product.

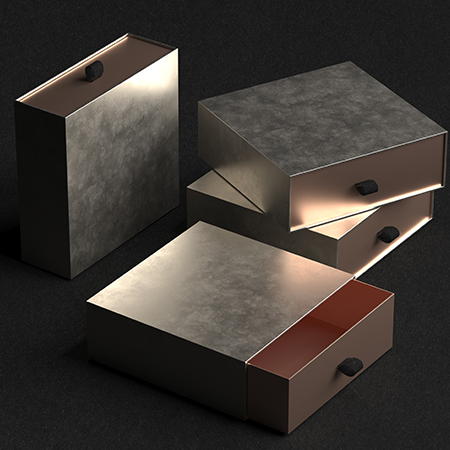

2. COMPLETION PROCESS

After the manufacturing process is completed, the packaging must be assembled. This can take many forms depending on the nature of the product. Some examples are:

- Is the packaging a simple box the product will sit in?

- Does the packaging require a separate supplement to surround the product?

- Are assembly and filling automatic or manual?

These are just a few of the many points to consider during the completion process. Both product and packaging must be protected while speeding up the process.

3. TRANSPORT OF THE PRODUCT

When the packaging is complete, the product will be transported to where it is sold. The protection of the product is imperative in this important step. Whether it is delivered by land, sea, or air, some steps need to be taken to preserve the integrity of the product and this is a point that should be included in packaging design. Consider shipping the product and take measures to protect it. It should be noted that in addition to protecting the packaging and the final product, packaging efficiency is also important when it comes to logistics. Well, thought out packaging can reduce costs during shipping.

4. SHELF LIFE

Shelf life is another area to consider in package design. While we are most familiar with a shelf life for perishable products, shelf life also represents how well the product will look on the shelf. From tamper protection to fragility, these should be considered in advance.

5. USER EXPERIENCE

The last step in the packaging process is the user's experience. Industry-leading brands know this and highly value this part of the packaging process. In addition to protecting the product, the packaging should create an experience for the consumer. It should tell a story and build customer loyalty.

GET PROFESSIONAL SUPPORT FOR PACKAGING STAGES

For a brand's packaging to be successful in the market, each of the different stages of packaging development must be well thought out. With this aim in mind, it is very important for each brand to get help from trained professionals. At LuxBoxPack, we have extensive experience in packaging helping numerous brands achieve their goals. Contact us now to find out how we can guide you and your brand in each of these stages.