BLOG

Tips, news and updates about the packaging and paper industry world

Anatolian Patterns and Packaging: The Identity Encoded by Geography into Design

Packaging design is not merely an expression of aesthetic choices - it is also a medium through which cultural accumulation, geographical memory, and historical continuity are revealed. In this context, Anatolian patterns move beyond being simple visual ornaments in packaging design and become carriers of a deeply rooted identity narrative. Bearing the traces of thousands of years of civilizations, the geography of Anatolia offers brands a powerful, authentic, and distinctive narrative ground through its language of patterns. The fundamental strength of Anatolian patterns lies in their rich symbolism. From kilim motifs to tile ornaments, from geometric forms to vegetal embellishments, this visual language embodies concepts such as abundance, protection, continuity, belonging, and balance. Each motif used on packaging conveys these meanings to the consumer, consciously or unconsciously. That transforms packaging into not merely a visual surface, but a cultural storyteller. Another prominent aspect of these patterns in packaging design is their timelessness. Anatolian motifs possess an aesthetic understanding that transcends period-specific trends. When combined with modern design approaches, they establish a balanced bridge between the past and the present. Traditional patterns supported by minimal typography can convey a stance that is both contemporary and deeply rooted. This synergy becomes a strong point of reference, particularly for brands in search of identity. Geographical belonging is one of the most distinctive values that Anatolian patterns bring to packaging. In a world where similar visual languages are repeatedly reproduced on a global scale, local motifs give brands a distinctive character. This character communicates not only “where it comes from,” but also “what it is grounded in.” In this way, packaging subtly yet effectively emphasizes the product’s origin. A significant consideration in the use of Anatolian patterns is restraint and the manner of interpretation. A literal and excessive application of these motifs can turn packaging into a purely decorative object. Contemporary packaging, however, requires these patterns to be interpreted, simplified, and applied in a contextually appropriate way. While the essence of the pattern is preserved, its form is updated, allowing tradition to become a natural component of modern design. In short, Anatolian patterns are not merely a visual choice in packaging design - they are a strategic design element that brings together cultural memory, geographical identity, and narrative power. When handled thoughtfully, packaging does more than wrap the product - it carries the story of the land it belongs to through a refined and elevated language. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Intercivilizational Design: The Convergence of Eastern and Western Aesthetics in Packaging

Packaging design today has gone far beyond being merely an element that protects or transports a product. In contemporary practice, packaging is regarded as a field of communication that makes cultural codes, aesthetic perspectives, and historical accumulations visible. In this context, the convergence of Eastern and Western aesthetic approaches in packaging design enables both the enrichment of design language and the creation of a more inclusive narrative for brands on a global scale. Eastern aesthetics largely derive their origins from tradition, symbolism, and a profound relationship with nature. Minimal yet meaning-laden forms, symmetrical patterns, calligraphic elements, and natural color palettes constitute the fundamental building blocks of this approach. In packaging design, this distinctly Eastern perspective imparts a sense of timelessness and serenity to the product. Especially in food, cosmetics, and traditional product categories, this aesthetic language helps establish an emotional connection with the consumer. Western aesthetics, by contrast, present a design approach focused on functionality, clarity, and user experience. Modern graphic layouts, typographic boldness, readability, and ergonomics are prioritized. In Western-centered packaging designs, the message is direct and concise - the consumer forms a quick and rational relationship with the product. This approach plays an effective role, particularly in fast-moving consumer goods and industrial packaging solutions. The meeting of Eastern and Western aesthetics in packaging creates a hybrid design language that brings the strengths of these two distinct approaches together. For example, when the functional and systematic structure of the West is supported by the symbolic and narrative elements of the East, balanced packaging solutions emerge in terms of both aesthetics and communication. Such designs offer a multilayered experience not only visually but also culturally. For businesses operating in globalized markets, this synthesis serves as a significant tool for appealing to consumers across different geographies. The language of packaging moves beyond belonging to a single culture and transforms into a universal narrative. That allows brands to gain acceptance in diverse markets without detaching from their origins. In summary, the concept of intercivilizational design transforms packaging into not merely a protective tool but a bridge between cultures. Packaging designs that unite the depth of the East with the rationality of the West provide contemporary businesses with a powerful communicative foundation that offers meaning and context beyond aesthetics. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Can New Packaging Trends Be Powered by AI?

The packaging industry has a dynamic structure that is directly influenced by technological developments and rapidly integrates these advancements into its design processes. In recent years, the widespread adoption of AI technologies across many fields, from production to logistics, has introduced a new way of thinking in packaging design as well. At this point, the frequently asked question is: Can new packaging trends truly be powered by AI? One of the most prominent contributions of AI to packaging design is its data-driven analytical capability. The examination of consumer behavior, purchasing habits, shelf interactions, and visual preferences through large data sets enables design decisions to move away from intuition and be based on measurable data. In this way, packaging can reach the audience in a manner that is not only aesthetic but also functional and clear. Another significant area of impact is the acceleration of the design process. AI-supported tools can generate various combinations of colors, forms, and graphics in a short time and present alternative scenarios to the designer. That should be regarded not as a complete automation of the creative process, but as a support mechanism that expands the designer’s decision-making capacity. The collaboration between human creativity and machine learning lays the groundwork for the emergence of new aesthetic languages in packaging design. The role of AI is also increasingly evident in sustainability-oriented packaging trends. Optimizing material usage, reducing unnecessary waste, and developing more efficient packaging solutions with fewer resources can become more predictable through AI algorithms. That makes it possible for environmental concerns to be taken into account at the early stages of the design process. AI also strengthens the concept of personalized packaging. Packaging designs that can be adapted in line with regional preferences, cultural differences, or seasonal consumer trends help brands establish more flexible and responsive communication. This approach paves the way for moving away from a one-size-fits-all packaging mindset and creating more targeted and meaningful designs. In short, rather than being a sole determining factor in packaging design, AI is positioned as a powerful tool that fuels new trends. When used correctly, AI technologies bring together the aesthetic, functional, and sustainability dimensions of packaging, becoming a significant driving force shaping the future of the industry. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Power of Symbols: How Brands Integrate Hidden Messages into Packaging?

In today’s consumer landscape, packaging is far more than a protective shell - it is a strategic touchpoint where brands communicate their identities, values, and emotional promises through an invisible language. At this touchpoint, symbols emerge as quiet yet compelling storytellers. They speak directly to the consumer’s subconscious, are instantly recognizable, and carry meaning across cultures. By leveraging this power, brands embed hidden messages into their packaging, allowing the product to speak without words and enabling brand values to be understood without being explicitly stated. One of the biggest advantages of symbolic expression is its immediacy. A consumer often makes a decision within seconds in front of the shelf. Within such a short window, lengthy texts, detailed explanations, or complex graphics struggle to make an impact. A symbol, however, can instantly evoke perceptions of trust, naturalness, innovation, or premium quality. A minimal line can suggest simplicity; a geometric shape can imply order; a nature-inspired icon can signal sustainability. When deliberately chosen, these symbols transform packaging into a silent guide that reinforces the product’s positioning. Brands use symbols not only as aesthetic elements but also as strategic devices that build layers of meaning. Messages about a product’s origin, production method, or philosophy can be encoded through iconography. A circular form may represent continuity and cyclicity; a triangular structure may imply progress or balance; a hand motif may evoke craftsmanship and human touch. Paired with color, these symbols gain even more depth - blue reinforces trust, green suggests naturalness, and golden hues strengthen a premium perception. Thus, the consumer sees not merely a decorative element, but senses a brand promise. Cultural symbolism also plays a critical role in embedding hidden messages into packaging. Certain motifs, patterns, or signs may hold different meanings across societies. For this reason, designers must carefully interpret both the cultural codes of the target audience and global associations. Otherwise, a symbol’s intended meaning may turn into an unintended implication. Successful brands navigate this with meticulous analysis, opting for symbols that carry universally positive connotations. In summary, symbols are invisible yet powerful narrators within packaging design. When brands skillfully employ this silent language, packaging becomes more than a surface - it evolves into a meaningful communication platform that conveys the product’s character, values, and story. This layered narrative, shaped by symbols, influences the consumer’s decision-making process, consciously or unconsciously, and further amplifies the strategic significance of packaging. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Green Production Practices: Energy Efficiency and Packaging Design

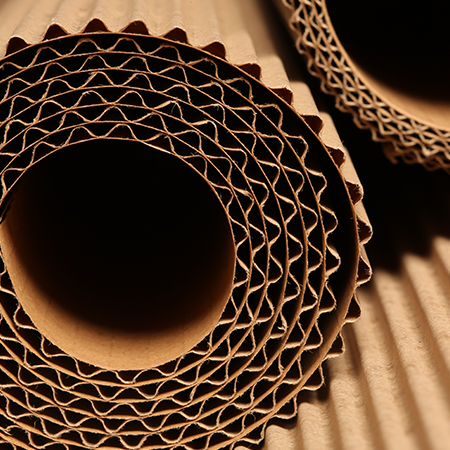

Sustainability today is not merely an environmental policy - it represents a broad transformation spanning production, design, logistics, and consumer habits. The packaging industry stands at the very center of this shift, as packaging directly influences the amount of energy used in manufacturing, the volume of material consumed, and the overall carbon footprint. For this reason, green production practices integrated with energy efficiency offer long-term strategic value for both businesses and the planet. Energy efficiency is one of the most tangible starting points of green production. Optimizing machinery in production facilities, improving heating and cooling systems, recovering waste heat, and incorporating renewable energy sources all generate significant savings in packaging manufacturing. A production model that consumes less energy not only reduces costs but also lowers the carbon emissions associated with the packaging’s lifecycle, an approach that aligns seamlessly with sustainability goals. Packaging design, meanwhile, is the unseen complement of energy efficiency. A well-designed package enables the use of materials that require less energy to process, favors lightweight structures, and supports cutting techniques that minimize waste. For instance, lightweight materials reduce energy consumption not only during production but also throughout logistics. More compact and stackable designs take up less space during transportation, helping lower fuel consumption. Another essential dimension of green production is the circular economy approach. Choosing recyclable, reusable, or biodegradable packaging materials can significantly influence the amount of energy needed in production. Materials with a high percentage of recycled content greatly reduce the energy required to generate raw materials. Conscious material selection by designers is therefore a critical step toward meaningful sustainability. Today’s consumers pay closer attention than ever to the environmental sensitivity of brands. However, communicating this awareness should not rely solely on marketing messages - it must be reflected directly in production processes. Packaging design centered on green production practices and energy efficiency provides businesses not only with environmental responsibility but also with long-term competitive advantage. In short, the relationship between energy efficiency and packaging design is becoming increasingly defining. Sustainable packaging supported by eco-friendly production models optimizes resource use and reduces businesses’ carbon footprints, offering a tangible contribution toward a more livable future. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Winter Aesthetics and Packaging: What Do Cool Tones Evoke in Consumers?

Winter is a season in which nature slows down, colors become more subdued, and tones gain a calmer identity. Using winter aesthetics as a robust reference in packaging design is not merely a seasonal choice; it stands out as a strategic approach that directly engages consumer psychology. The use of cool tones, particularly blue, gray, white, and ice-like textures, can create multiple effects on perception, emotion, and behavior. Consumers often associate cool colors with concepts such as “cleanliness,” “simplicity,” “purity,” and “reliability.” For this reason, packaging languages inspired by winter aesthetics are frequently preferred for products focused on health, technology, care, and hygiene. A cool palette creates the impression that the product is functional, orderly, and controlled. Especially when combined with minimal typography, it forms a cohesive expression that reinforces perceptions of simplicity and professionalism. Winter tones not only evoke a sense of emotional coolness but also offer an effective way to stand out on the shelf. Within a category dominated by warm hues, the use of a calm blue or frosted gray creates visual contrast. This contrast establishes a quiet yet assertive presence that draws consumer attention without shouting. Thus, winter aesthetics can be viewed as a strategy for standing out in highly competitive visual categories. The use of cool tones in packaging can also strengthen perceptions related to product freshness. In the food sector, design elements that evoke ice or snow intuitively convey that the product is preserved, refreshing, and reliable in terms of shelf life. That is particularly effective for brands aiming to create a “freshness perception” without relying on cold-chain logistics. Another aspect of incorporating winter aesthetics into packaging is its power to create an emotional atmosphere. Winter is associated with feelings such as calmness, clarity, stillness, and sometimes nostalgia. Cool tones and simple compositions used on packaging can open the door to these emotions in the consumer’s mind. In this way, the product goes beyond being merely a functional object and offers a mood-based experience. In short, winter aesthetics in the world of packaging is not just a seasonal trend but a design approach that influences consumer behavior, shapes perception, and offers brands both aesthetic and strategic advantages. Cool tones are powerful tools that intuitively convey simplicity, trust, freshness, and professionalism. When used correctly in packaging design, they hold the potential to create a striking and lasting communications impact. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Architecture of Perception: Does the Visual Hierarchy of Packaging Influence Consumer Decisions?

Packaging design presents a visual language that directly affects consumer decisions, serving as one of the first elements noticed on the shelf. One of the core concepts underlying this language is the “visual hierarchy.” Visual hierarchy refers to the way information, colors, sizes, and layouts are organized on a package, shaping the consumer’s eye movement, attention, and perception. Visual hierarchy fundamentally relies on three elements: size, contrast, and focal point. Prominent colors or large typography immediately capture the consumer’s attention, while information presented in smaller or more subdued tones is perceived subsequently. This arrangement determines which information the consumer acquires first about the product and provides unconscious guidance in the purchasing decision. For example, in a premium product, emphasizing the brand logo enhances the perception of quality, while carefully positioned product features highlight functional value. Color usage also plays a critical role in visual hierarchy. Vivid and saturated colors quickly attract attention, whereas pastel or neutral tones serve a supportive role. That is especially effective in complex shelf arrangements, ensuring the product is noticed rapidly. Proper use of contrast helps significant information stand out and guides the consumer perceptually. The impact of visual hierarchy is not limited to attracting attention; it also has the capacity to tell a story. The visual arrangement on packaging conveys the product’s identity, purpose, and value intuitively. As a result, even at first contact, the consumer perceives the brand message and priority information about the product. This unconscious guidance stands out as a mechanism that accelerates decision-making and enhances trust. In summary, the visual hierarchy of packaging is a powerful tool that shapes consumer behavior. Strategic use of size, color, and contrast can direct perception and influence purchasing decisions. For designers, it is a discipline where aesthetics and functionality converge; for brands, it is a critical component of differentiation and perception management. Packaging does more than enclose a product - it creates a mental priority map for the consumer and consciously structures the purchasing experience. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Identity of Geography: Reflections of Mediterranean Aesthetics in Packaging Design

The function of packaging design extends beyond merely protecting or transporting a product; it also serves as a medium through which brands convey their cultural and aesthetic values to consumers. Mediterranean aesthetics offer a visual language distinguished by color palettes, textures, and organic forms. This design philosophy reflects the identity of the region in packaging, endowing products with character and creating an emotional connection with the consumer. The distinctive colors of the Mediterranean (olive green, sea blue, and the warm tones of the sun) bring a natural appeal to packaging. These hues provide aesthetic satisfaction while offering cues about the product’s geographical origin. For example, when used in food packaging, such tones reinforce perceptions of naturalness and freshness. Similarly, organic textures in packaging materials, along with natural motifs like olive branches or stones, carry the region’s cultural heritage into the design and emphasize the product’s uniqueness. The influence of Mediterranean aesthetics on packaging design is not limited to visual appeal; it also aligns with brands’ sustainability approaches. Designs inspired by the region’s natural resources, when combined with recyclable or eco-friendly materials, offer consumers both aesthetic and ethical value. This factor is significant in supporting the conscious choices of modern consumers. Accurately reflecting Mediterranean identity in the design process requires meticulous attention to detail. When color, texture, form, and material selection come together, packaging transcends its role as a mere physical container; it becomes a storyteller, conveying the region’s aesthetics and cultural values. Through such packaging, consumers form an emotional and cultural connection with the product, making the purchasing experience more meaningful and memorable. In short, Mediterranean aesthetics serve as a profound source of inspiration for packaging design. The colors, textures, and cultural motifs of the region not only enhance a product’s visual appeal but also establish emotional communication with consumers. This approach transforms packaging from a simple protective tool into a form of cultural and aesthetic expression. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Transparency and Trust: How Transparent Packaging Influences Purchasing Behavior?

Consumer behavior is shaped not only by the tangible quality of a product or its perceived price, but the packaging itself also plays a crucial role in purchasing decisions. Transparent packaging, in particular, has become a prominent element in modern consumer trends. Such packaging provides high visibility of the product, fostering a sense of trust in the consumer and positively influencing their purchasing inclination. One of the key advantages of transparent packaging is that it allows the product to be seen directly. When consumers have direct information about the contents, it minimizes disappointment stemming from unexpected surprises or unmet expectations. For instance, in the food sector, being able to observe the contents of a packaged product visually enhances perceptions of freshness, quality, and hygiene. This factor becomes especially significant today, as trends toward healthy living and natural products are on the rise, directly affecting consumer trust. Transparent packaging not only increases product visibility but also serves as a significant tool for creating brand awareness. By observing the product, consumers evaluate the brand’s approach to transparency and honesty. That plays a critical role in fostering loyalty and building long-term trust. Psychologically, a visible product gives the consumer a “sense of control,” enabling them to make a more informed purchasing decision. However, there are certain considerations to keep in mind when using transparent packaging. Choosing appropriate materials and designing the packaging correctly is essential to maintain product freshness and quality. Poor-quality or improperly designed transparent packaging can negatively affect product perception and undermine the sense of trust. Therefore, businesses must balance transparency with durability and protective functionality. In summary, transparent packaging is one of the most powerful tools shaping consumer behavior today. Transparency establishes a direct link between trust in the product and consumer satisfaction. By taking these factors into account in packaging design, businesses and brands can not only display their products accurately but also cultivate a trust-based relationship with their consumers. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Limits of Minimalism: Is a Logo-Free Packaging Approach Possible?

Minimalism has long been a dominant direction in the world of packaging. The idea of simplicity, clarity, and the removal of all unnecessary elements is frequently embraced by brands, both for aesthetic appeal and ease of use. Yet a more radical question has been gaining attention in recent discussions: Is it possible to design packaging entirely free of logos? Answering this goes beyond a visual preference; it requires a thorough evaluation of brand identity, consumer psychology, and market behavior. At its core, a logo-free packaging approach is built on the idea of creating a “silent identity.” In such designs, what defines the product is not a graphic element or a typographic mark, but often the packaging’s form, color, or texture. Whether it is possible to create a recognizable identity without explicit brand elements has long been debated - especially among global brands. Nevertheless, certain sectors, particularly cosmetics, personal care, and premium food products, have seen a rise in designs that either eliminate the logo or push it significantly into the background. One of the key motivations behind this approach is the desire to evoke a sense of “simplicity and transparency” in the consumer. When the logo recedes, the packaging offers an experience free from overt branding, presenting the product as more natural and understated. In many cases, the consumer’s attention shifts from the brand’s visual identity to the product’s inherent qualities, a significant advantage in categories where the content itself is the primary point of value. However, logo-free packaging comes with a major challenge: brand recognizability. In today’s crowded marketplace, a product’s ability to stand out on the shelf still relies heavily on brand markers. For this reason, a completely logo-less approach can only become sustainable when supported by a strong visual language or a distinctive packaging form. Consistency in color palette, the use of unique textures, and even the geometry of the packaging can give a brand a personality capable of standing on its own without a visible logo. Another essential factor is sustainability. Minimalist, logo-free packages often use less ink, fewer printing layers, and more natural surfaces. In this sense, they can represent an intersection of clean aesthetics and environmental awareness. Reducing printing on recyclable materials in particular helps minimize both production costs and environmental impact. In short, logo-free packaging is certainly possible, but under specific conditions. A brand must cultivate a distinctive visual system, a strong material vocabulary, and a consistent sense of form. When executed properly, this approach, which pushes the boundaries of minimalism, has the potential to give brands a silent yet remarkably powerful identity. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Vintage Breeze in Packaging: How Traces of the Past Shape Today’s Designs?

Today, packaging is far more than the outer layer that protects a product; it has become a carrier of cultural narrative and brand memory. In recent years, largely influenced by global brands, the “vintage” aesthetic has regained prominence in packaging design. At its core lie feelings of nostalgia, familiarity, and trust in the past. Yet the vintage trend is not merely an aesthetic choice; it represents a multilayered design approach that connects consumer psychology, material selection, and visual language. This design mindset, which brings traces of the past into the present, often draws inspiration from the graphic styles of the 1950s through the 1980s. Handwritten-style typography, slightly faded color tones, and simplified illustrations frequently appear in these designs. Such elements evoke a sense of a “trusted and familiar” product for consumers. That is precisely why vintage packaging is especially favored in food, personal care, and beverage industries: the design subtly suggests that a modern product is backed by a long-standing heritage. The vintage aesthetic is not limited to graphic elements; the textures of the materials used also reinforce the story. Matte papers, kraft textures, embossed prints, and metallic tin containers are key tools that bring the retro visual world to life. When paired with sustainability trends, these materials create a brand identity that is both eco-friendly and nostalgic. The rise of kraft-based packaging, in particular, reflects a tangible desire for naturalness and a meaningful connection to the past. Another key influence of the vintage movement is the transformation it brings to brand storytelling. Today’s consumers care not only about what a product is, but also “where it comes from” and “what values it embodies.” For this reason, packaging that evokes past design eras gives brands an opportunity to communicate their roots, craftsmanship, or cultural heritage. Simplified color palettes and nostalgic symbols stand out as visual cues that enrich this narrative. Of course, the vintage approach is not suitable for every brand; however, it is a powerful, expressive tool for those whose target audience seeks simplicity, trust, and authenticity. Moreover, because it is a timeless visual language, it is not easily swayed by trends. That extends the shelf life of the packaging and lends long-term aesthetic consistency to the brand. In summary, the vintage breeze in packaging is more than an aesthetic preference: it is a strategic design approach where cultural memory, consumer psychology, and sustainability trends intersect. Inspiration drawn from the past, combined with the needs of the present, becomes a powerful communication tool that adds both character and depth to contemporary brands. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

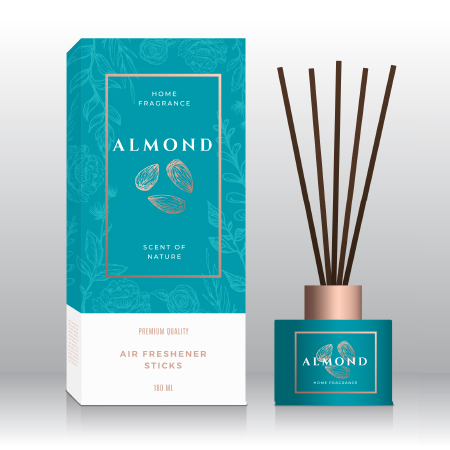

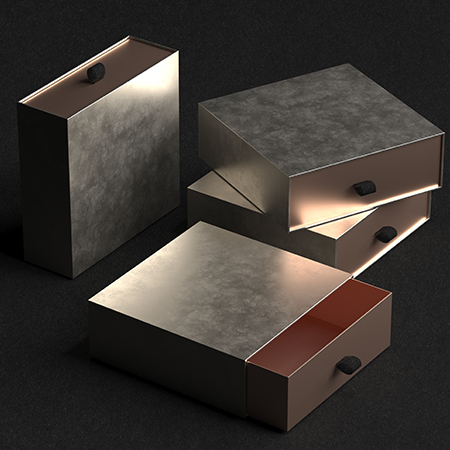

The Palette of Luxury: Which Colors and Tones Dominate Premium Brand Packaging?

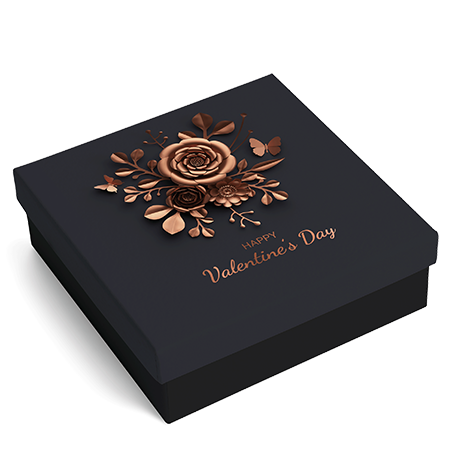

For brands operating in the luxury segment, packaging serves not only to protect the product but also to reflect the brand’s identity, values, and aesthetic approach. Color and tone choices in premium packaging directly influence consumer perception, acting as a key element in reinforcing the product’s “luxury” appeal. So, which colors and tones are most prominent in this realm? Traditionally, black and white emerge as the quintessential duo in luxury packaging. Black conveys sophistication, strength, and timelessness, while white represents simplicity and elegance. When combined with minimalist designs, these colors effectively communicate prestige and quality in high-end products. Black packaging is particularly common in jewelry, watches, and fashion, often accented with metallic tones such as gold or silver to highlight logos or design details. Metallic tones -gold, silver, and bronze- are another prominent element in luxury packaging. These colors impart a sense of value and exclusivity while ensuring that the packaging stands out on the shelf. Metallic accents are typically applied sparingly and strategically rather than across the entire package, creating visual appeal without appearing excessive. Premium brands also skillfully incorporate pastel shades. Soft beiges, cream tones, and blush pinks are especially prevalent in cosmetics and perfumery. These colors reinforce the perception of a delicate, high-quality product and contribute to a sophisticated appearance. The combination of the packaging material’s texture with the color palette engages both touch and sight, further enhancing the sense of luxury. In recent years, neutral and earthy tones have increasingly appeared in luxury packaging. Browns, stone grays, and cream shades are often chosen by brands emphasizing sustainability and natural values. Using these tones signals that the brand aligns not only with aesthetics but also with principles and lifestyle choices. In short, the dominant colors and tones in premium brand packaging typically consist of a carefully curated mix of black, white, metallic, pastel, and neutral shades. Each selection is made with precision to reflect the brand identity, the quality of the product, and the desired emotional response in consumers. In luxury packaging, colors do more than appeal visually: they act as the very language of sophistication. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

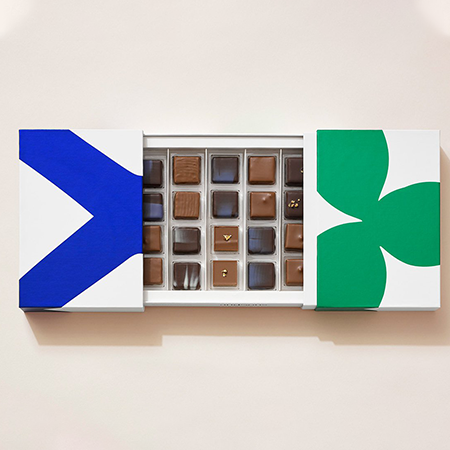

The Language of Form: What Does a Box Shape Say About a Brand and Product?

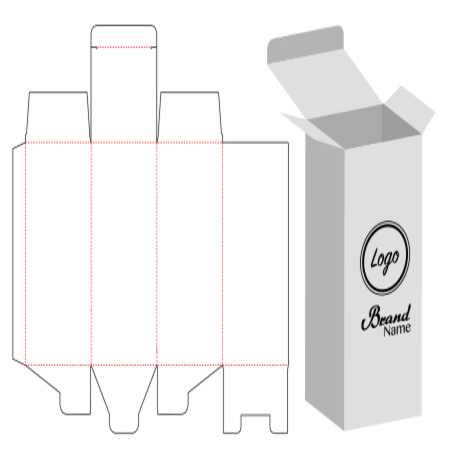

In packaging design, it’s not only colors and tones that communicate, but also the shape itself. Box forms convey the character of the product and the values of the brand through a visual language. For premium brands, the right shape choice reinforces the perception of luxury and strengthens the emotional connection with the consumer. Rectangular and square boxes typically convey messages of order, balance, and reliability. When combined with minimalist and elegant designs, these geometric forms suggest a solid, trustworthy product. These shapes are frequently used in cosmetics, perfumes, and premium chocolate packaging, helping brands present a classic and timeless image. Cylindrical and round boxes offer a different narrative. Soft curves suggest that the product provides a graceful and fluid experience. In products where tactile experience is significant, such as shampoos, creams, and perfumes, these shapes provide both aesthetic and ergonomic advantages. Round forms also evoke warmth and approachability, making them a popular choice for certain premium products. Unique and custom shapes highlight a brand’s distinctiveness and innovation. Asymmetrical boxes, specially cut designs, or surprise-opening packages attract consumer attention and indicate that the product is not only functional but also experience-focused. Such packaging is ideal for limited-edition luxury items, creating a sense of collection value and prestige. In short, the shape of packaging communicates subtle yet powerful messages about the product and the brand. Rectangular and square forms symbolize reliability and order; cylindrical and round forms express elegance and approachability; and unique designs convey a brand’s innovative and prestigious identity. Premium brands skillfully use this language of form to make their products valuable not only visually, but also experientially. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Future of Packaging: How Can Artificial Intelligence Shape Design Trends?

Packaging design is not only about protecting a product; it also involves conveying brand identity, enriching user experience, and supporting sustainability goals. Therefore, every new trend in packaging emerges at the intersection of consumer behavior and technological advancements. In recent years, the most powerful element positioned at the center of this transformation has been artificial intelligence. AI not only provides speed or automation in design processes; it also stands as a tool that expands creativity, builds data-driven decision systems, and delivers personalized experiences. Brands can now analyze consumer habits in real time, interpret color psychology or form preferences through data, and ultimately create packaging designs that speak more accurately to their target audience. Another significant shift is the redefinition of aesthetic perception through AI. The intuitive approach of designers is, of course, still a core value; however, AI supports this intuition with forward-looking prediction models. For example, while designs focused on naturalness and minimalism may dominate during a certain period, AI can offer insights into how organic textures or digital art influences might evolve in the future. In this way, design trends are shaped not only by creative interpretation but also by dynamic data streams. AI also plays a major role in sustainability. Material optimization, supply chain planning, and the development of recyclable structures are now largely supported by algorithms. As a result, packaging reaches a more comprehensive point in terms of both aesthetics and environmental responsibility. When we consider user experience, we see the rise of personalized packaging. AI makes it possible to create custom designs for specific customer segments. That represents a shift from traditional mass-focused design approaches to a more micro-targeted strategy. In short, AI is not merely accelerating packaging design but giving it a new vision. In the future, designs will be shaped by intuition fueled by data, sustainability values, and a user-focused creative approach. Meanwhile, the packaging industry will continue to be one of the most visible stages of this transformation. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Packaging and Consumer Psychology: The Role of Packaging in Creating a Sense of Belonging to a Community

Today's consumer does not merely purchase a product; they invest in a lifestyle, a culture, and a community where they can feel a sense of belonging. At this point, packaging acts as an invisible communication bridge created by brands. As the first touchpoint with the user, packaging is more than an aesthetic surface: it is a space where values, emotions, and social identity are reflected. Communities built by brands nurture the consumer's desire to see themselves as part of a group. In this context, packaging design serves as a symbol. Color choices, typography, textures, and minimalist or bold design approaches offer clues about the target audience. A product sitting on a shelf is not just a physical object but a visual response to the question, "Do you belong to this world?" When users see the values represented by the brand in the packaging and form a connection, a sense of belonging emerges beyond the product itself. With digitalization, the concept of community has diversified further. Now, users join brand communities not only through physical experiences but also through online interactions. Shareable packaging on social media, consistency in visual identity, and design elements that support storytelling play a critical role in building these digital communities. Many consumers choose brands not only for aesthetics or function, but also for a sense of loyalty to the world the product represents. For a sense of belonging to be sustainable, packaging must offer a holistic experience. Ease of use, environmental awareness, tactile details, and a premium feel reinforce the thought, "I am in the right place." Therefore, packaging is no longer only a protection element; it is a silent yet powerful carrier of brand community identity. In short, packaging is gaining importance as a strategic element that builds a sense of belonging in consumer psychology. When designed correctly, it not only carries the product but also the culture to which the brand belongs; it makes the user feel like part of a bigger story through the product they purchase. In this sense, packaging is the invisible architect of belonging to a community. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Role of Light in Packaging: The Psychology of Glossy, Matte, and Translucent Surfaces

Beyond being a protective element for a product, packaging is a silent salesperson and a canvas reflecting brand identity. In packaging design, the way the surface interacts with light profoundly affects consumer perception, just as much as the choice of color, shape, and material. Different surface finishes, such as glossy, matte, and translucent, trigger consumers' expectations and emotional responses towards the product. This article will examine the role of light and surface psychology in packaging. Glossy Surfaces: Luxury and Dynamism Glossy or 'glos' surfaces reflect a high amount of light, creating a captivating sheen. Psychologically, glossiness is often associated with high quality, luxury, and modernity. These types of surfaces are perceived as more dynamic and energetic. In the consumer's mind, a glossy package often signals newness, cleanliness, and smooth content. Therefore, they are frequently preferred for cosmetics, technology, and premium food products. A disadvantage of glossy surfaces is that they make fingerprints and minor flaws more noticeable. Matte Surfaces: Naturalness and Reliability Matte (low-sheen) surfaces diffuse light and absorb it rather than reflecting it. That gives them a soft, velvety, and tactile feel. The psychological equivalent of matte packaging is typically seriousness, naturalness, calmness, and reliability. Avoiding excessive brightness, this finish reflects a plain and minimalist aesthetic, which is why it is preferred for handicrafts, organic products, and certain pharmaceutical packaging. Consumers tend to find matte surfaces less assertive and more 'genuine.' Translucent and Transparent Surfaces: Honesty and Hints Translucent (not opaque, but allowing light to pass through) or completely transparent packaging offers a hint about the product or fully reveals the product itself. That sends a message of honesty and transparency. Especially in the food and beverage industry, the visibility of the product signifies freshness and quality assurance. Translucency, on the other hand, can imply a mysterious quality or the texture of the contents. The use of these surfaces in packaging design builds a high level of trust and sincerity regarding the contents. In short, the choice of surface in packaging is not a mere aesthetic preference but is directly related to consumer psychology and the values the brand wishes to convey. Each surface, by the way it interacts with light, profoundly influences the product's perceived value and character. The careful selection of these surfaces will continue to be a critical part of the design strategy. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

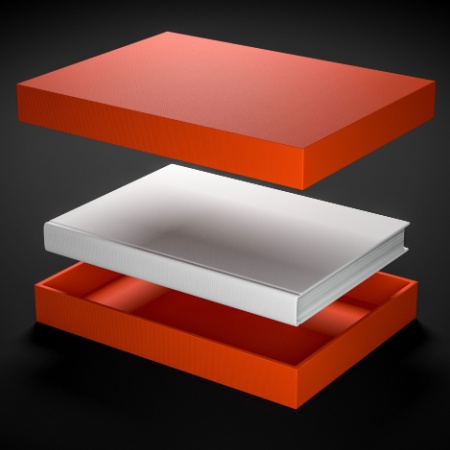

Essential Elements in the Packaging Design of Premium Perfume Brands

Perfume is a declaration of identity; it presents an emotion, a perspective, or a philosophy distilled into essential oils. Yet, the first point of contact with this essence -its packaging- carries a message about the product's quality and the brand's prestige that is at least as powerful as the content itself. For brands in the premium segment, packaging is not merely a protective casing, but an integral part of marketing, brand identity, and the sensory experience. In this article, we will examine the fundamental elements that distinguish high-end perfume packaging from ordinary products and are considered essential in their design processes. Material Selection: Driving the Sensory Experience The cornerstone of luxury packaging is the quality and texture of the materials used. Premium brands spare no expense, opting for the highest standards of materials. The Bottle: Heavy, thick-based, and flawless glass conveys a sense of stability and elegance. The transparency and clarity of the glass highlight the perfume's color and purity. The Cap: Materials such as metal alloys, weighted plastics, or treated wood are employed. The weight of the cap and its distinct "click" sound enrich the tactile experience of the product and underscore its quality. Magnetic caps are also a popular choice that enhances this luxurious sensation. The Outer Box: High-grammage, specially textured, matte, or glossy finished paper and cardboard are utilized. The box may include velvet interior linings or custom-cut foam supports to make the unboxing ritual feel special. Minimalism and Iconic Silhouettes in Design The premium segment generally adopts timeless and distinct designs, steering clear of excessive ornamentation. The bottle's form must create an iconic silhouette that reflects the brand's DNA. Simplicity: Clean lines and geometric forms are preferred over complex decorations. This simplicity ensures that the focus remains on the product itself. Brand Icon: Many renowned perfumes possess instantly recognizable bottle forms that have remained unchanged for years. That symbolizes the brand's heritage and permanence. Ergonomics: Attention is paid to details that improve the user experience, such as ensuring the bottle fits perfectly in the hand and the cap opens and closes easily. Impeccable Craftsmanship and Quality Hidden in the Details Every process executed on the packaging must reflect the brand's commitment to perfection. Imperfections in craftsmanship can instantly damage the perception of luxury. Printing Techniques: The brand name and logo are typically applied using methods such as embossing (relief), hot foil stamping, or high-precision silk-screening. The use of gold, silver, or metallic colors provides a rich luster under light. Labeling: Instead of traditional labels, inscriptions are more often etched directly onto the glass with acid or applied using permanent printing techniques. That eliminates the risk of the label peeling or deteriorating. Collection and Limited Editions: For special series, extra craftsmanship elements come into play, such as crystal cuts, handmade details, or embellishments resembling precious stones. Color Palette and Perception Management The packaging's color choice should support the perfume's olfactive profile and the target audience's perception. Black and Gold: Reinforces the perception of absolute luxury, elegance, and evening use. Transparent and Light Tones: Represent fresh, light, and daytime fragrances. Dark-Colored Glass: Implies the richness and depth of rare, oriental, or woody notes. In short, premium perfume packaging goes beyond merely protecting a product; it is the silent ambassador that whispers the brand's story and offers the consumer a special ritual. The combination of design, quality, and sensory details elevates these products to the pinnacle of packaging art. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Crystal Effect in Packaging: The Allure of Light-Reflecting Materials

In the world of packaging, every detail influences how a product is perceived and the emotional bond it establishes with consumers. For designers, light is just as significant as color, texture, and form. The way light refracts or reflects on a package’s surface is a powerful factor that shapes a product’s visibility on the shelf, how it’s perceived, and its overall aesthetic value. In recent years, more brands have embraced reflective materials in their packaging to harness this “crystal effect.” The Power of Gloss – Depth in Visual Perception: Packaging materials that create a crystal effect stand out with the way they capture and reflect light. Unlike flat, matte surfaces, these materials offer a multidimensional shine that elevates the product from an ordinary object to one that appears precious. The optical play of glossy, reflective surfaces is especially favored by brands positioned in the luxury segment. Refined Material Technologies: Creating a crystal effect involves more than simply using transparent or glossy materials; surface treatment techniques also play a key role. Metalized coatings, high-gloss varnishes, holographic printing, and special light-diffusing films allow for controlled light direction and reflection. As a result, the package serves not only as protection but also as a showcase for the product itself. Luxury Perception and Sensory Experience: Light-reflecting packaging is often associated with luxury and elegance. The human eye is naturally drawn to glossy surfaces, making crystal-effect packaging more visible on the shelf. Gloss not only provides visual impact - it also creates a tactile impression. Hard, smooth, and transparent surfaces lend the product a sense of value and refinement. Sustainable Brilliance – Balancing Aesthetics with Environmental Awareness: For a long time, crystal-effect packaging was linked to environmentally unfriendly materials. However, new-generation solutions, such as recyclable metalized surfaces and light-reflecting composite materials, are changing this perception. Today, brands can embrace striking aesthetics without compromising their environmental responsibilities. Minimalism Meets Sparkle: The crystal effect isn’t exclusive to elaborate designs; it can also create striking results in minimalist and elegant packaging. The contrast between matte surfaces and glossy accents brings crystal brilliance and modern design together in harmony. This balance achieves a look that is both sophisticated and contemporary. In short, the crystal effect in packaging design is not merely an aesthetic choice - it is a powerful communication tool. The strategic use of light gives brands both visual appeal and a prestigious stance. The allure of glossy surfaces continues to hold a permanent place in the modern packaging landscape. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

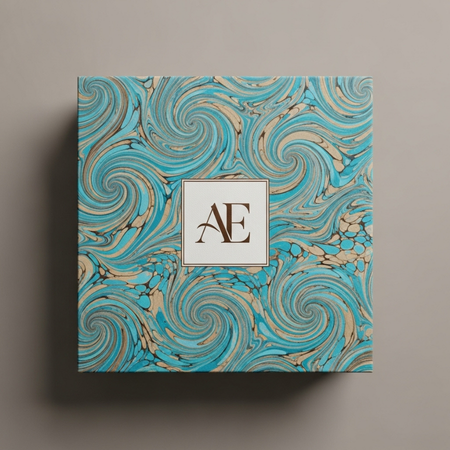

Globalized Local Trends: Packaging Approaches Inspired by Turkish Culture

Packaging not only protects a product from physical factors but also carries its story far and wide. Around the world, brands enrich their identities through design approaches inspired by local cultures. This trend becomes even more pronounced in countries like Türkiye, where cultural heritage runs deep. Packaging designs rooted in Turkish culture create a strong emotional bond with local consumers while standing out in international markets, adding layers of meaning to the products they contain. Transforming Cultural Codes into a Visual Language: The millennia-old richness of Turkish culture offers packaging designers a unique source of inspiration. The geometric patterns of Ottoman tiles, the rhythmic repetitions of carpet motifs, and the fluid forms of ebru (marbling) art are being reinterpreted with contemporary design sensibilities. This approach not only enhances the aesthetic value of packaging but also infuses it with a sense of belonging. In doing so, the package itself transcends its practical function and becomes a cultural vessel. Local Becomes Global – Standing Out in International Markets: Today, many brands reflect their cultural origins in their designs to capture global attention. Packaging inspired by Turkish culture grants brands a distinctive identity, particularly in the gastronomy, textile, and cosmetics industries. For example, packaging influenced by traditional copper engravings may offer foreign consumers an exotic aesthetic while evoking a sense of nostalgia and familiarity among locals. This dual effect allows brands to build cultural bridges. Elegance of Tradition in Minimalist Designs: Modern packaging trends emphasize minimalism and functionality. Yet when this clean aesthetic meets the refined details of traditional Turkish arts, the result is an exceptionally sophisticated look. Fine lines, soft color transitions, and symbolic patterns give contemporary packaging a sense of historical depth. This way, the designs maintain their connection to local roots while aligning seamlessly with global standards. Sustainability and Cultural Responsibility: Incorporating cultural elements into packaging design is not merely an aesthetic choice but also a matter of responsibility. Authentic, respectful, and sustainable designs support both environmental awareness and cultural consciousness. By blending local motifs and techniques with modern materials, designers build a bridge between tradition and the future. In short, packaging approaches inspired by Turkish culture offer brands in a globalized world the opportunity to tell powerful stories. This trend is more than an aesthetic preference - it plays a crucial role in preserving cultural identity and carrying it into the future. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

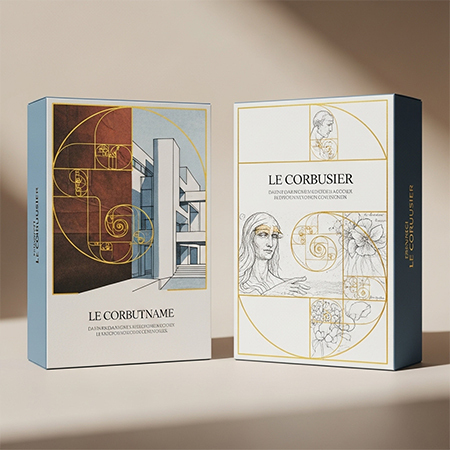

Collectible Packaging: The Antiques of the Future?

For a long time, packaging was viewed merely as a functional tool to protect a product. Today, however, that definition has far exceeded its limits. Packaging has evolved into a powerful design object that reflects a product’s identity, style, and quality. This transformation has also paved the way for certain packages to transcend their functional role and become collectible objects. But could these special designs one day become the antiques of the future? What Makes a Package Collectible: One of the key traits of collectible packaging is its ability to withstand the test of time. A carefully constructed visual language that departs from the ordinary distinguishes these designs from the rest. Limited production, fine craftsmanship, the use of innovative materials, or the power to represent a cultural era are all factors that enhance their value. Packaging design, therefore, requires a strategy that considers not only the present but also how it will be remembered in the future. Silent Witnesses of Cultural Memory: Packaging serves as a silent witness to the aesthetic sensibilities and production culture of its time. A soda bottle from the mid-20th century or a vintage chocolate box, for instance, is more than just packaging - it is a design object that reflects a way of life. Today, this perspective is being reinterpreted through contemporary design approaches. Brands are increasingly investing in packaging that may carry such cultural significance in the future. The Role of Sustainability and Durability: A package’s collectible value depends not only on its aesthetics but also on its physical durability. Packaging made from high-quality, long-lasting materials has a greater chance of being preserved over time, making it a potential “antique of the future.” Materials such as glass, metal, thick cardboard, and wood are particularly valued in this regard. Art, Design, and Emotional Connection: Collectible packaging forms a bond with consumers that goes beyond an ordinary purchase. This connection often stems from aesthetic appreciation or nostalgic evocation. Designs that flirt with art further amplify this emotional resonance. Leaving Traces for the Future: A package that seems ordinary today may become a symbol of its era years from now. For designers and manufacturers, this perspective introduces a new responsibility: to create not something fleeting, but something enduring. In short, packaging design not only reflects today’s consumer habits but also shapes the aesthetic heritage of the future. That is why collectible packaging may one day be displayed in museums - not as relics of the past, but as the antiques of tomorrow. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Art Movements to Draw Inspiration From When Designing Packaging

Packaging is more than just a protective layer for a product - it is its storyteller. Through elements such as color, texture, shape, and typography, it weaves a narrative. For this reason, packaging design is one of the most vivid fields where aesthetics and visual culture come to life. One of the most effective ways to enrich this complex process is to draw inspiration from art history. Different art movements not only enhance visual language but also create strong emotional connections. Bauhaus – Perfection in Simplicity: Emerging in Germany in 1919, the Bauhaus movement became one of the cornerstones of modern design through its principle of “form follows function.” Drawing inspiration from the Bauhaus in packaging design allows for a clean yet striking look, free from unnecessary ornamentation. Straight lines, geometric shapes, and limited color palettes create a timeless aesthetic. This approach is especially effective in industries such as technology, cleaning, and personal care, where it conveys reliability and professionalism. Art Nouveau – The Fluid Language of Nature: Developed at the end of the 19th century, Art Nouveau stands out with its flowing lines, floral motifs, and elegant typography inspired by nature. Translating this movement into packaging design creates a romantic and sophisticated atmosphere, particularly for sensory products such as cosmetics, perfumery, or gastronomy. Organic lines and intricate patterns add character and depth to the product. Pop Art – The Language of Color and Boldness: Rising in the 1950s, the Pop Art movement brought everyday objects to the center of art, establishing a bold and eye-catching visual language. Bright colors, strong contrasts, and graphic elements give Pop Art-inspired packaging an energetic and youthful character. This style is a powerful tool for brands in sectors such as food, beverages, and fashion that seek dynamism. Minimalism – The Aesthetic of Quiet Strength: Minimalism is the art of saying more with less. In packaging design, minimalism stands out through the bold use of white space, simple typography, and monochromatic accents. This approach conveys a sense of confidence in the product’s quality and merges simplicity with prestige. Cubism – Redefining Form: Cubism breaks objects down and reassembles them from multiple perspectives. In packaging design, this approach can be used to create unexpected geometric compositions, asymmetric layouts, and a sense of depth. It supports a refined and artistic stance. In short, art movements add more than just aesthetic value to packaging design - they give products a distinctive personality. Choosing the correct artistic language can transform a product from a simple shelf item into a meaningful experience. For designers, art history remains an inexhaustible source of inspiration. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Packaging in the Age of Climate Crisis: Communicating Sustainability Through Design

The climate crisis, one of the most critical challenges of the 21st century, is profoundly transforming not only the energy, transportation, and production sectors but also the packaging industry. As one of the most visible faces of the production chain, packaging has become a tangible medium through which brands express their environmental stance. Today, packaging design is not merely a field with aesthetic or logistical implications; it is also gaining significance as a visual and material-based expression of sustainability. Communicating a sustainability message through packaging is not a one-dimensional design choice but a comprehensive communication strategy. This strategy requires a multi-layered approach, from the materials used and the design language to production methods and recycling processes. For example, biodegradable materials or recycled papers not only reduce environmental impact but also intuitively convey a brand’s environmental responsibility to the consumer. The very texture, color, and appearance of these materials carry an implicit message: “This product was created with the planet’s future in mind.” The shape of the packaging itself is another element that reinforces the sustainability message. When simplified forms stripped of unnecessary layers are combined with a minimalist design language, they not only reduce resource consumption but also help ensure the message is perceived clearly. Moreover, reusable or easily recyclable packaging structures play a quiet yet powerful role in raising environmental awareness among consumers. Visual elements such as color palettes and typography also form part of this narrative. Natural tones, matte finishes, clean typefaces, and minimal icons are powerful tools that support the theme of sustainability. This approach creates an environmentally conscious brand image in the consumer’s mind while turning the packaging itself into a medium of communication. In summary, in the age of the climate crisis, packaging design plays a critical role not only in protecting or transporting products but also in making environmental awareness visible. This understanding transforms packaging into a silent yet powerful ecological storyteller. When material choices, structural decisions, and design language come together, packaging ceases to be merely a protective shell and becomes a symbol of a stance toward the planet’s future. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

The Role of Cultural Motifs in Packaging Design in the 21st Century

In the 21st century, as globalization accelerates, brands strive to differentiate themselves not only through product quality but also through the layers of meaning embedded in the experiences they offer. One of the most visible surfaces of these meaning layers is packaging design. Packaging is no longer merely a protective element; it has evolved into a significant communication tool that carries cultural identities, local narratives, and aesthetic values. In this transformation, the role played by cultural motifs is becoming increasingly evident. Cultural motifs reflect a society’s historical memory, belief systems, symbolic narratives, and artistic aesthetic sensibilities. Their use in packaging design provides brands with a space for differentiation in the global market while creating a strong emotional bond with local consumers. From Anatolian kilim patterns to Japanese origami forms, from African geometric lines to Scandinavian minimalism, many cultural references are being reinterpreted in contemporary packaging design. That allows products to transcend their status as mere consumer goods and turn into cultural experiences. Modern packaging design disciplines prefer not to directly replicate cultural motifs but to reproduce them within a contemporary aesthetic language. This approach both honors the origin of the motif and adapts it to the dynamic visual world of today. For example, a traditional motif can be simplified and integrated into a logo, or combined with modern typography to create a strong visual balance. Another key function of cultural motifs in packaging design is to evoke a sense of belonging. Consumers feel a stronger affinity for familiar symbols and stories. That transforms packaging from a purely visual element into a meaningful carrier of cultural significance. Such an approach also contributes to the preservation of cultural diversity and the visibility of local production cultures. In summary, 21st-century design thinking approaches cultural references not as decorative accessories but as value systems. Packaging designers go beyond treating these values as embellishments and instead position them as powerful symbols integrated into the brand’s overall narrative. For this reason, cultural motifs stand out as the silent yet compelling storytellers of contemporary packaging design. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Color Psychology and Packaging: Strategies That Influence Consumer Emotions

In packaging design, color is not merely an aesthetic element but also a powerful tool that directly influences consumer psychology because a product must stand out among dozens of alternatives on the shelf and convey the right message. At this point, the meanings and emotions carried by colors are among the critical factors that guide purchasing decisions. Red evokes energy and dynamism while also stimulating appetite. For this reason, it is frequently chosen in food and beverage packaging. Blue represents trust and loyalty; in health products, technology, and corporate brands, it strengthens the emphasis on reliability. Green symbolizes naturalness and sustainability, whereas black is often associated with luxury, prestige, and mystery. Yellow highlights optimism and joy; however, if not used carefully, it may become overstimulating. When selecting colors for packaging design, the cultural codes of the target consumer audience must also be taken into account. Perceptions of color can vary significantly across cultures. For example, while white is associated with purity and simplicity in the West, it may symbolize mourning in some Asian cultures. Therefore, for global brands, a color strategy is not merely an aesthetic choice but also requires a sociocultural analysis. Colors, when used not only individually but also in combinations, create strong effects on consumers. Contrasting colors make it easier to attract attention, while tone-on-tone combinations, different shades of the same color, establish a sophisticated and cohesive perception. In addition, the harmony that color forms with the texture, material, and typography of the packaging reinforces the overall message. Neuropsychological research shows that colors trigger emotional memory in the decision-making process. Consumers do not rely solely on rational evaluation; the feelings evoked by packaging also shape purchasing behavior. Therefore, a color strategy should not only align with the brand’s identity but also meet the emotional expectations of consumers. In summary, interpreting color psychology correctly in packaging design provides brands with a powerful strategic advantage. Through colors, an emotional bond can be built with consumers, and the value promised by the product can be communicated more effectively. Thus, every color choice is not only a visual decision but also a conscious communication strategy. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Luxury or Simplicity: Striking the Optimum Balance in Premium Packaging

Packaging is not only a shield against external factors for the product, but also one of the most powerful elements that creates and supports brand perception. Especially for brands in the premium segment, the message conveyed by packaging design is just as important as the quality of the product itself. At this point, brands often face a fundamental dilemma: should they highlight luxury or simplicity? The answer is neither one nor the other. What needs to be done is to strike the right balance between the two approaches. Packaging that evokes luxury often reveals itself through opulent details, rich color palettes, and striking textures. Gold-foil prints, velvety surfaces, or heavy materials make the consumer feel that they are encountering a valuable product. However, today’s perception of luxury does not rely solely on ostentation. Minimalist designs can create an equally sophisticated image. In fact, the modern consumer can label a design that is stripped of excess yet refined as “luxurious.” Simplicity, on the other hand, brings clarity and a sense of trust to the forefront. Boxes dominated by white, clean typography, or monochromatic prints can reflect a brand’s transparent and honest approach. Yet, packaging that is overly simplified may not fully communicate the product’s premium nature. That is why it is crucial for the design to embody both minimalist aesthetics and subtle details. Changes in consumer expectations make finding this balance even more critical. Generations Y and Z are particularly drawn to environmentally friendly, sustainable, and elegant packaging. Thus, today’s understanding of premium packaging is shaped not only by visual splendor but also by ethical values and a responsible approach to production. In summary, the optimum balance in premium packaging lies in blending the elegance of luxury with the refined power of simplicity. Neither too ostentatious nor too plain: a well-balanced design that aligns with the identity of the product and brand leaves a lasting impression on the consumer. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Packaging Trends Inspired by Scandinavian Minimalism

In recent years, Scandinavian minimalism has become a strong source of inspiration not only in interior design and furniture but also in the packaging industry. Built on the principles of simplicity, functionality, and naturalness, this approach allows brands to establish a more straightforward yet effective connection with consumers. One of the primary elements in minimalist packaging design is the elimination of unnecessary visual clutter. Instead of complex patterns, heavy color transitions, and distracting graphics, clean typography, simple color palettes, and the effective use of white space take center stage. In this way, the product itself comes forward with its authenticity and content, while the packaging simply frames it with elegance. Another significant feature of Scandinavian aesthetics is respect for nature. In packaging, this manifests in the preference for recyclable or biodegradable materials. Papers with wooden textures, cartons in natural tones, or glass-like transparent materials emphasize environmental sensitivity while also fostering a sense of trust in consumers. Functionality is also an inseparable part of Scandinavian design philosophy. Packaging does not merely offer an aesthetic surface but also provides ease of use. Boxes that can be easily opened and closed, reusable containers, or ergonomic forms are among the elements that enhance user experience. In this sense, minimalism goes beyond simplicity to support a practical lifestyle. Typography, with its clean yet strong expression, plays a decisive role in minimalist packaging. Large, bold, and legible typefaces communicate the product’s identity directly and without exaggeration. This approach creates a simple but trustworthy impression at the consumer’s first encounter with the product on the shelf. In summary, packaging trends inspired by Scandinavian minimalism bring visual simplicity, functionality, and environmental awareness together, carving out a meaningful place in modern consumer culture. This design language is not merely an aesthetic choice but also a cultural approach that reflects lifestyle values. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Green Image in Consumer Perception: Strengthening Sustainability Messages Through Packaging

Today, sustainability is not only an environmental policy but also one of the key elements of trust and reputation in consumer perception. Packaging plays a critical role in making brands’ eco-friendly approaches visible, as it is the first point of contact with the product and directly shapes the consumer’s sense of a “green image.” The first way packaging strengthens the sustainability message is through material choice. Recyclable paper, biodegradable plastics, or reusable glass containers do more than provide environmental benefits; they also empower consumers to make more conscious decisions. Such materials reflect a brand’s environmental responsibility in a tangible way, reinforcing trust. Another factor supporting the green image is the visual design language. Natural-inspired colors, visuals reminiscent of leaves or earthy textures, and minimalist typography all reinforce sustainability messages visually. Simple yet clear designs foster a sense of sincerity, while avoiding exaggerated claims makes the brand’s commitment more believable. Transparency is also a crucial part of consumer trust. Certifications, recycling symbols, or short notes about the product’s environmental impact displayed on packaging help consumers establish a more informed relationship with the brand. These details show that the green image is not merely a marketing tool but an adopted responsibility. Functionality and reusability further enhance the sustainability message. Foldable boxes, refillable packaging, or multipurpose storage containers provide practical solutions in daily life while simultaneously strengthening environmental awareness. In summary, packaging is not only a means of protection but also a powerful communication platform that makes a brand’s sustainability commitments visible. When material choice, design language, transparent information, and functionality come together, the green image in the consumer’s mind becomes not just a perception but a lasting value built on trust. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Retro Inspirations in Packaging: Creating Modern Designs Inspired by the Past

Today, packaging design does more than merely protect a product; it also establishes an emotional connection between the consumer and the item. Designers who aim for this connection to be strong and impactful often look to the past for inspiration, drawing from retro influences. Retro design blends the aesthetic codes of bygone eras with contemporary trends, evoking a sense of nostalgia while offering modern consumers a distinctive experience. Packaging with retro touches typically draws from the visual elements of the 1950s, 1960s, or 1970s. The color palettes, typography styles, and patterns used during these periods still create a compelling visual language today. For instance, pastel tones, rounded and flowing lines, or geometric patterns are characteristic features of retro designs. These elements create striking contrasts in modern packaging, helping products stand out on store shelves. A key approach in applying retro design to contemporary packaging is maintaining balance. Elements copied solely from the past may not meet the expectations of today’s consumers. Therefore, retro features should be used minimally and strategically. For example, classic typography can be paired with a modern box form, or a nostalgic color palette can be complemented with contemporary graphics. In this way, the packaging references the past while presenting a current design aesthetic. Retro touches in packaging can also forge a strong connection with the brand story. Designs inspired by the past evoke feelings of trust and authenticity in consumers. This approach is particularly common in food, beverage, and personal care products, as consumers respond positively to the “familiar and safe” sensation that nostalgic designs convey. Moreover, retro design does more than recall the past; when applied correctly, it highlights the brand’s modern and innovative aspects as well. In summary, packaging design enriched with retro inspirations is an effective way to bring the aesthetics of the past into the modern world. By blending nostalgic elements with current trends, designers can create packaging that is visually striking and emotionally engaging. This approach transforms packaging from merely a protective container into a tool for communication and experience. At LuxBoxPack, we provide packaging solutions tailored to the evolving needs of our clients in different sectors. Contact us at +90 212 438 82 15 to get detailed information about our product range. ...

Packaging in the Era of Circular Economy: Strategies for Reuse and Redesign