Die cutting method is a common technique of production within the packaging industry. It includes the use of a die for cutting soft materials into a number of packaging styles and shapes. The ability to mass-produce custom packaging is where the true value of the die cutting process lies. In this article, we'll be exploring the die cutting process and its role in custom packaging.

Understanding the process

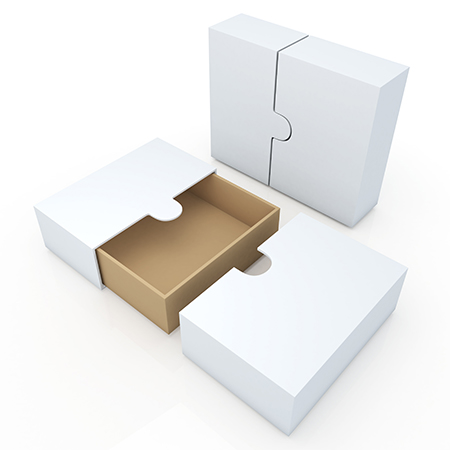

A cutting die is basically a giant cookie cutter which is pressed into the material to create the desired packaging shape.

Die-cutting in the wake of the industrial revolution has come a long way from its roots in the shoemaking industry.

Originally designed to assist mass packaging production, die-cutting has developed into a flexible manufacturing tool.

Cutting die can be used to create virtually any form, style, or pattern.

Custom packaging is made with the aid of custom steel dies and die cutting machines.

This manufacturing form allows packaging to be mass-produced but, more importantly, ensures precision.

How is a cutting die made?

Developments in cutting die technology and production techniques ensure that die cut boxes have the most efficient and reliable design. Typically Computer Aided Design ( CAD) generates the packaging outline.

This digitized drawing will be moved to a piece of hardwood called a die board.

The most advanced way to draw designs on die boards is by using state-of-the-art laser cutters to burn them onto the wooden surface.

Incorporating lasers in this process has made the drawing on the die board more accurate.

The cutting die uses metal strips called rules, or rules of steel. The cutting rule is shaped by means of a rule bender, which bends, cuts and notches steel into the appropriate shape.

The die cutting method can employ a variety of cutting rules. Each rule has its own purpose and implementation, depending on the packaging complexity.

Some of the most common rule options are:

- Through Cutting: Through cutting cuts all the way through the packaging material.

- Scoring: Rather than cutting the whole way through the material, scoring leaves an impression indent or partial cut on a single stress point.

- Creasing: Creasing is similar to scoring where the die creates a fold line on the packaging material. Unlike scoring, creasing allows for inward bending of the material by having two parallel stress points. Havings two stress points allow for greater flexibility of the material.

- Perforating: Perforating involves indenting a line of holes along the design material. The design is not separated from the material itself but can easily detach along the perforated lines.

Each rule is designed to suit material thickness and flute size. The steel rules are pounded down by hand onto the die plate. A variety of foam and rubber pieces are then glued onto the die. Such parts help the die bounce off the corrugated board during manufacture.

The die cutting machine firmly pushes the die into the cardboard resulting in a cut out shape (remember the cookie cutter).

This cut out has several lines, creases and folds that are used to manually assemble the packaging, depending on the complexity of the packaging design.

The excess material is then stored and recycled for further use.

It is expensive to create individual dies for each piece of packaging. However, when several orders of the same product are made over time, it is a one-off expense which is balanced.

Die-cutting techniques

Die-cutting is in fact still very analog and manual. While technology is used in the process, a manually made cutting die is still the fastest method for mass-produced, custom packaging.

In packaging the most popular die-cutting techniques are:

Flatbed Die Cutting:

Flatbed dies are made with a flat, rectangular piece of hardwood (die board) that contains the unique die shape.

It involves the use of a cutting die, that is firmly pressed into the cardboard by a flatbed machine.

Flatbed die machines have a small blank size, so they are not suggested for larger designs. However, they are capable of making intricate, detailed designs such as small cut-outs, tight cuts and slit scores.

Rotary Die Cutting:

Rotary cuttie dies are made with a cylindrical press and rolled over the cardboard rather than pressed down like the flatbed die cutter.

Rotary die cutting is a much quicker process and is ideal for mass production of simple designs.

Some rotary die-cutting machines can even perform two functions at once, such as embossing, lamination, etc.

Although producing higher volumes at a faster rate, rotary cutting machines aren’t always the best option.

The type of technique/machine used depends on the design and desired functionality of the packaging.

Digitalised die cutting

Developments in technology within the industry has digitalised the die cutting process. The traditional methods are still the most prominent and frequently used; however, it is now possible to die cut packaging without the use of steel knives.

These highly advanced machines use computerised controls and lasers to make the cuts in the place of steel rules.

Despite the advancements in technology, digitalised die cutting machines are limited in their capabilities.

They are a viable option for low-medium order volumes however are not yet as fast as analogue methods/machinery.

The Finishing Touch in the Die Cutting Process

The die-cutting process enables custom packaging which is truly unique. Intricate, elegant design offers a touch of sophistication in luxury packaging that will leave a lasting impression on the consumer.

But what if we took the luxury theme further?

There are a variety of finishing techniques which accentuate the custom packaging die-cut design. This focus on packaging design resonates with customers and impacts their potential buying decisions in a positive way.

Check at some of the finishing options that are most common and get the most out of your die cut boxes:

Embossing

Embossing is a printing technique which makes the print higher off the packaging surface. The embossing machine produces an exquisite finish which can not only be seen but felt by the customer.

High temperature pressure gives rise to the embossing effect. A metal die (similar to a cutting die) is made, which is then used to emboss the desired surface.

It is also possible to deboss-the opposite of embossing, by pushing the logo under the surface of the packaging. The effect produces an indented finish look.

This is better combined with high-quality die cut packaging such as a rigid box, whether it's an embossed or debossed finish.

UV Print

UV printing takes advantage of the ultraviolet curing technology during printing. After going through the printer the packaging material receives wet ink that is directly exposed to UV light.

The exposure to the UV light immediately dries the ink, preventing seepage or ink spreading during the process. This method provides the perfect accompaniment to a well crafted die cut box with sharp, vibrant printing.

Hot Stamping

Hot stamping is a custom packaging finishing technique which uses high temperature to glue foil or dry paint into a desired shape.

The finishes are pressed on with a die that transfers the heat. Hot stamping is great in combination with other finishing techniques , for example embossing or debossing.

This type of finish would work well with a tailor made box like a magnetic box.

Final Thoughts

The die cutting process allows for the production of a wide variety of custom packaging solutions. The system ensures design precision but also allows for high volume output.

The varied die cutting methods, equipment, and designs give a range of packaging functions. This feature distinguishes custom packaging from generic packaging, allowing endless possibilities.